Any time a vehicle’s suspension changes, whether it be a lift kit, towing, or hauling you will notice a difference in how it drives. To help combat those issues on our 2019 Chevrolet Silverado, we reached out to Hellwig Products who has a host of products to help in towing and non-towing applications.

We went with their rear sway bar (PN 7780) and the Pro Series helper springs (PN 61912) to help control the truck better on-road and while towing. Before diving into what we thought of each product, we will look at how each helps in their own way.

The helper springs we ended up going with would allow us a tunable spring rate with a simple installation. To find out more about the products, we spoke with Mike Hallmark of Hellwig products.

“Helper springs maintain a level ride height under heavily loaded conditions providing enhanced control, maximum comfort, and driver confidence,” Hallmark said. “Hellwig Helper Springs are a ‘set it and forget it’ load control solution.”

From towing a trailer or being loaded down with gear the helper springs can cover it all. They have a level load support ranging from 500 pounds to 3,500 pounds with a wide range of applications.

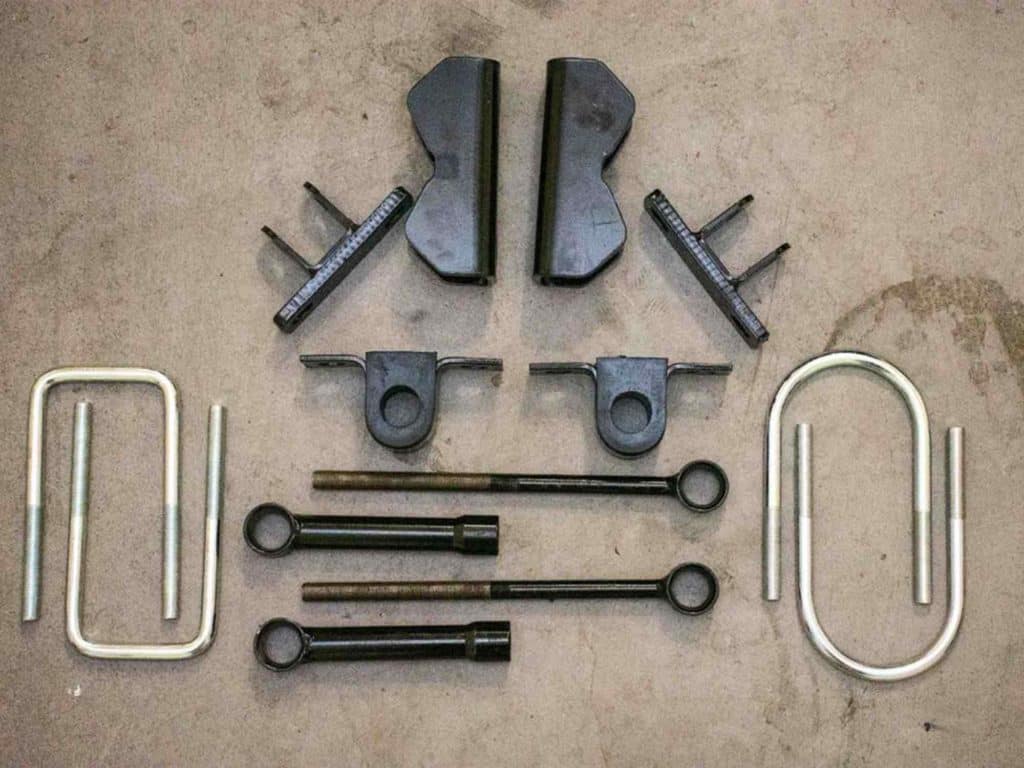

Installing the helper springs did not require any fancy tools and installed in a little over an hour. The springs sit on top of the factory leaf spring pack and do not require any disassembly of the factory setup.

The helper springs came with isolators that sat between the factory leaf pack and the helper springs. Being adjustable, we did not need to worry if we added more weight down the road as we would be able to adjust the springs for the new load.

When it got time to set the tension for the springs, we needed to lift the rear of the truck and take all the weight off the rear end. This allowed us to tighten the bolts holding the helper springs before placing the truck back on the ground to check the level.

We did need to do this a couple times to get the truck to sit where we wanted it to, but in the end the truck sat level.

CONTROLLING BODY ROLL WITH A REAR SWAY BAR

Sway bars can be a long topic of discussion in the off-road world as people have their pros and cons. We have had vehicles with and without sway bars, but the feeling of a truck, especially towing or lifted, outfitted with sway bars is second to none.

“Sway bars improve traction, distribute weight evenly, and are an easy bolt-on product,” Hallmark explained. “They are made from heat-treated 4140 chromoly steel and come with polyurethane bushings.”

Having our Silverado set up to do more towing and weekend off-roading, we knew that we needed a product to help in both areas as well as on-road driving. We wanted to have a better driving experience and less body roll to help in corning, high winds, and towing.

Like the helper springs, the rear sway bar was a bolt-on product that did not require us to remove any factory components. The sway bar bolted up to the rear axle easily, and the brackets for the end links tucked up nicely on the frame.

When setting the sway bar up, there are different holes to allow for more control. It is recommended to start at the furthest out hole and see how the vehicle performs before moving in closer. The sway bar should also be set up as close to parallel to the ground with the end links perpendicular to that.

With everything completed it was time to load up the truck and trailer and hit the road to see how Hellwig’s products changed the feel of the truck.

A NEW FEELING

Right off the start, we were able to notice a difference in how the truck felt. A quick trip around the neighborhood with our bed loaded with spare tires and gear, we could tell the truck was more planted on the pavement and did not lean like it did prior.

“Hellwig Steel Helper Springs and Sway bars combined provide optimal handling characteristics for any vehicle,” Hallmark said. “Hellwig Steel Helper Springs maintain a level ride height providing better weight distribution over the front and rear wheels. Hellwig Sway bars further enhance the handling characteristics by reducing the amount of body roll, providing better weight distribution from side to side of the vehicle when cornering or during evasive maneuvers.”

Hooking up the trailer is where we saw the biggest difference. Just attaching the trailer to the truck, we were no longer squatting or looking like we forgot to lift the rear of the truck.

Loading the trailer and hitting the road, we continued to feel the benefits of having both the helper springs and rear sway bar. The truck felt better than it ever had towing the trailer.

It is one thing to drive around with a new product and feel the difference, but when it comes to an unexpected test, that is when you can really tell. We had widened and lengthened the original trailer we had bought because our Class 2000 truck did not fit on it.

We were headed out to testing before its first race. Having a “new” trailer and “new” load can take a bit to make sure it is loaded properly. This we experienced first hand while on the freeway.

The trailer had been loaded with not enough tongue weight, and on the I-10 out by Palm Springs, the wind blew and sent the trailer fishtailing back and forth. It was a scary moment, but even in the midst of going between three lanes, it never felt like we couldn’t get control of the trailer.

This wasn’t the ideal test or a test we had even thought about doing, but we can say for certain if we did not have the helper springs or the rear sway bar, we would not have made it to testing.

Hellwig Products are proudly made in the USA with American steel and 2021 marks Hellwigs 75th anniversary, now on its fourth generation of Hellwig family leadership. Hellwig is here to support your journey, wherever it leads. For more information on Hellwig or to find products for your vehicle, be sure to visit their website.